Now that the bass drum unit is finished, we will work on the snare drum, the snare drum beater and the cymbal beater.

PHOTO A shows the unrestored snare drum which is the companion in

appearance to the bass drum we used. The previous mounting brackets will

be removed and replaced with brackets we fabricated to match the

appearance of the original brackets. As we did with the bass drum, the

snare drum is disassembled, the parts cleaned and reassembled. The size

of the snare drum was appropriate so no changes were made to the physical

size.

PHOTO A shows the unrestored snare drum which is the companion in

appearance to the bass drum we used. The previous mounting brackets will

be removed and replaced with brackets we fabricated to match the

appearance of the original brackets. As we did with the bass drum, the

snare drum is disassembled, the parts cleaned and reassembled. The size

of the snare drum was appropriate so no changes were made to the physical

size.

PHOTO B shows the completed drum. The beater mechanism operates from 2

Wurlitzer unit valves. The beater was disassembled, the valves rebuilt,

pneumatics recovered and the wooden parts sanded and refinished with

organ shellac.

PHOTO B shows the completed drum. The beater mechanism operates from 2

Wurlitzer unit valves. The beater was disassembled, the valves rebuilt,

pneumatics recovered and the wooden parts sanded and refinished with

organ shellac.

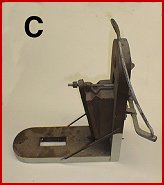

Since the case for the organ was missing and we are building it from

scratch, we have a choice of two configurations. Some Wurlitzer 105

organs appeared with the cymbal mounted on top of the case and some had

the cymbal mounted in front of the bass drum. I like the appearance of

the cymbal on the top of the case and decided to use that configuration.

I also had an original cymbal beater mechanism which could be rebuilt and

used. PHOTO C shows the unrestored beater minus the cymbal.

Since the case for the organ was missing and we are building it from

scratch, we have a choice of two configurations. Some Wurlitzer 105

organs appeared with the cymbal mounted on top of the case and some had

the cymbal mounted in front of the bass drum. I like the appearance of

the cymbal on the top of the case and decided to use that configuration.

I also had an original cymbal beater mechanism which could be rebuilt and

used. PHOTO C shows the unrestored beater minus the cymbal.

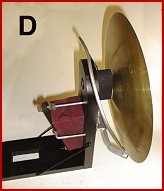

This unit was restored and a suitable size cymbal was attached. PHOTO D

shows the completed unit ready for mounting on the organ. Our 125 organ

has a similar decorative scroll on top which surrounds the cymbal and we

can use that as a pattern to fashion the scroll for the 105. We will use

the cymbal as a pattern to create the cutout area of the scroll.

This unit was restored and a suitable size cymbal was attached. PHOTO D

shows the completed unit ready for mounting on the organ. Our 125 organ

has a similar decorative scroll on top which surrounds the cymbal and we

can use that as a pattern to fashion the scroll for the 105. We will use

the cymbal as a pattern to create the cutout area of the scroll.

Dr. Bill Black is one of the nation's most knowledgeble Wurlitzer band organ experts. He has made recordings of many band organs and other mechanical music machines which are available for purchase at CarouselStores.com.